Product

Sunlit Sea delivers floating solar panels. Here you can read more about our product.

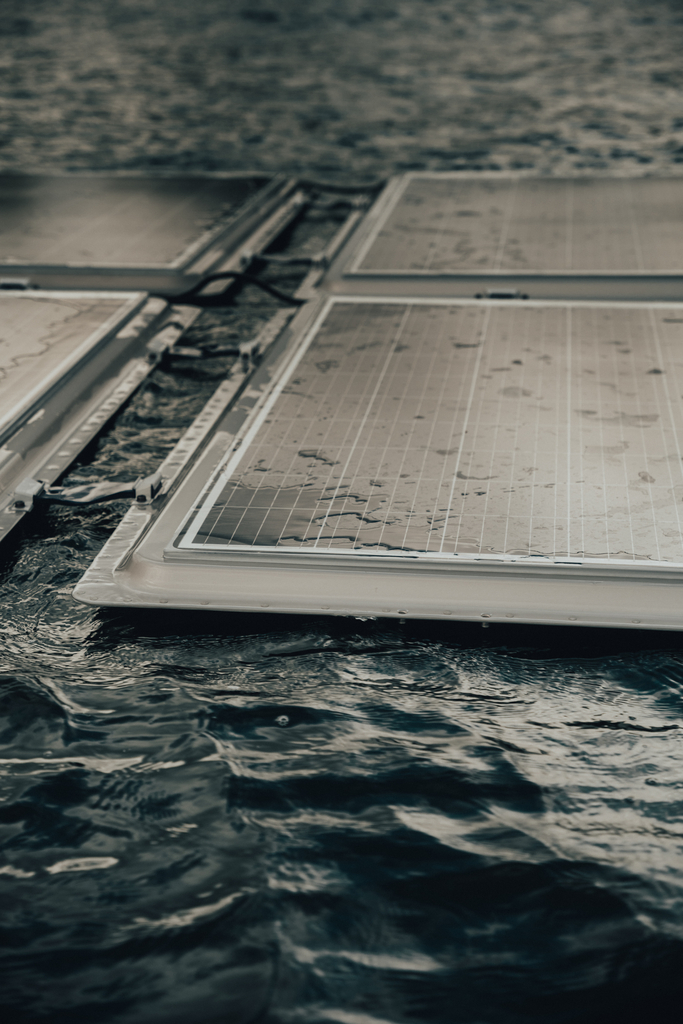

Floating Solar Panels

Sunlit Sea delivers prefabricated floating solar panel installations. The panels lay flat on the water, providing optimal cooling from the water underneath, excellent behavior on waves, and very high wind resistance.

Benefits of Sunlit Sea

Performance

01

Sunlit Sea's panels are designed for high efficiency, using water to cool and boost energy output

Read more about our solution

Benefits of Sunlit Sea

Resilience

02

Engineered for durability, they withstand extreme weather, ensuring consistent operation

Read more about our solution

Benefits of Sunlit Sea

Location

03

Can be installed on unused water surfaces, offering solutions to land scarcity

Read more about our solution

Benefits of Sunlit Sea

Deployment

04

Modular design allows for quick installation, meeting energy demands efficiently and scalably

Read more about our solution

Do You Have A Project In Mind?

Where Floating Solar Panels Shine

Cottages

Hydroelectric Dams

Desalination

Marinas

Dredging