Water poses some unique challenges to floating solar. Sealants are central

when preventing saline water from entering the inner parts between the panel

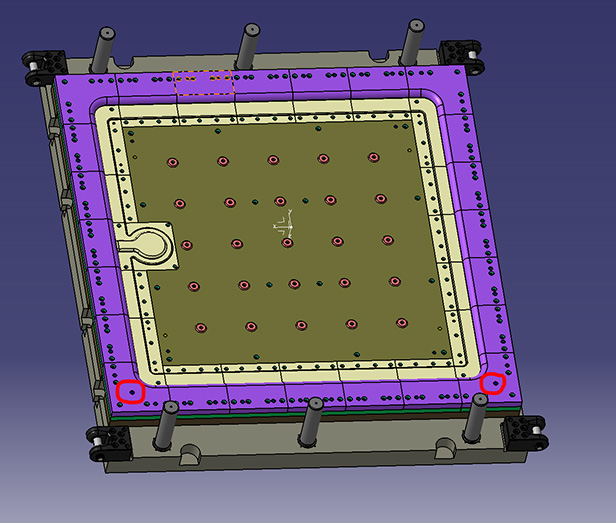

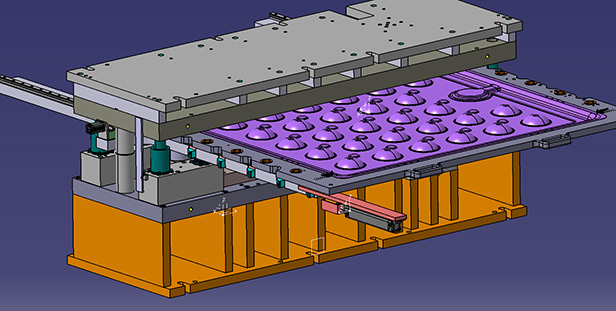

and the float itself. As part of our product development, butyl rubber (IIR)

is applied to the plateau of the float, protecting the bottom part of the

laminated solar panel.

By applying a glass/laminate cell module structure, the butyl offers a larger

degree of waterproofing, as compared to glass/glass cell module designs. Butyl

furthermore enables a frameless construction which is easy to maintain and

wash, with no mechanical fastening, leading to beneficial conductive traits

between the float and the panel itself.

In addition to a protective silicon barrier, different techniques have been

tested, including manually laying down the substance with a butyl gun, as well

as utilizing prefabricated butyl ribbons. Water intrusion may harm the solar

cells, cause corrosion or even jeopardize overall electricity production.

Therefore, all of the electronics are safely stored in a pit filled with a

potting material, isolating them from rough surroundings.

Double bonds in the molecular structure of the butyl rubber give it a

substantial packing density - making it more difficult for other molecules to

pass through. Partly due to its beneficial oxidation and ozone resistance

properties, various types of butyl are utilized in industrial applications

like tire production, pharmaceutical stoppers (sealing vials and bottles),

window strips, chemical gloves, to name a few.